ME values determined with especially enzyme technique were found lower than National Research Council (NRC)

14 values in this study. This may be due to different feed sources and enzymes used in studies which could change the research results

5. Stern et al.

15 reported that in the enzyme technique, enzyme activities in medium might be insufficient in comparison to those in ruminal medium. ME values determined by gas technique in incubations of 24 h were found generally higher than enzyme technique's. Çerçi et al.

16 reported that generally significant relations between ME and feed components with enzyme and gas technique were found, but grain feeds were not effective in determining of the prediction of the quality of feeds. In addition, they informed that positive high relationships between enzyme and gas techniques in the forages and protein sources were often found. Sileshi et al.

17 reported that nutrient components of feeds affected ME levels determined with gas technique. Nevertheless, Cone

18 has reported that a lower correlation has been found between the techniques when different enzymes were used in the same study. In this study, of which reasons are found different both enzyme technique and gas technique's of ME values than NRC

14 values may be due to nutrient components, used enzyme and incubation time

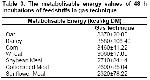

16,17. ME values determined by gas technique in incubations of 48 h were found closer to those of NRC (Table

3)

14. Incubation time were affected ME values of concentrates. In gas technique, rumen liquid's activity has an important role. It was announced that

12 different results might be found in same samples in gas technique, because it is needed many good conditions such as suited animal election, given feed amount to the animal and transported of rumen liquid in aneorobic conditions. In an another study

19, it was found to be 2.96, 3.09, 3.08, 2.58, 2.77, 2.13 and 1.87 Mcal/kg DM, respectively of barley, wheat, corn, oat, soybean meal, cottonseed meal and sunflower meal in incubations of 24 h in gas test. These results are agreed on partly with our study results.

Conclusion

ME values between enzyme and gas techniques were found significant statistically in concentrates. According to the results of this study, gas technique was found more utilizable than enzyme technique to determine ME levels of ruminant feeds.

Acknowledgments

This study was funded by TUBITAK.